what we do

dust

particulate matters

soot

oil fume

tvoc

Odor

- Efficiently remove welding smoke, oil mist and other gases, reduce the concentration of harmful exhaust emissions.

- Efficiently remove all kinds of dust sources inside the factory, such as ceramic grinding, stone cutting powder, to ensure that the workers' respiratory quality, reduce pneumoconiosis and other occupational diseases.

- Easy to clean and maintain or self-cleaning, low maintenance costs, long service time, easy maintenance.

- Can effectively recover dust, especially valuable powder, such as gold powder, polysilicon powder can be recycled twice.

- Compact size, easy to install and use a variety of sites.

- Remove fine particles in the factory office, accommodation and other environments, to provide healthy and safe indoor air for employees.

Product selection

FAC: Intelligent Clean Air Purification System

Intelligent cleaning and purification unit specially developed for the large space ventilation system

![]()

![]()

FKE: ESP Kitchen Exhaust Purifiers

FKE with ESP technology are designed to extract harmful particulates and odor from the kitchen fume so that the released kitchen exhaust is environmentally friendly and pollutant-free.

![]()

![]()

![]()

![]()

![]()

FAH: MESP AHU Air Purifier

FAH works as alternatives to media filters installed in AHU to remove the particles for indoor air powered by MESP tech. The filter is washable and reusable, resulting in low pressure drop and high efficiency efficacy.

![]()

![]()

![]()

![]()

![]()

FFC: MESP FCU Air Purifier

FFC is an innovative commercial air purification product, which is installed at the return air inlet of the fan coil, and automatically works with the fan coil to efficiently purify and sterilize the air through the MESP system.

![]()

![]()

![]()

![]()

![]()

Case Study

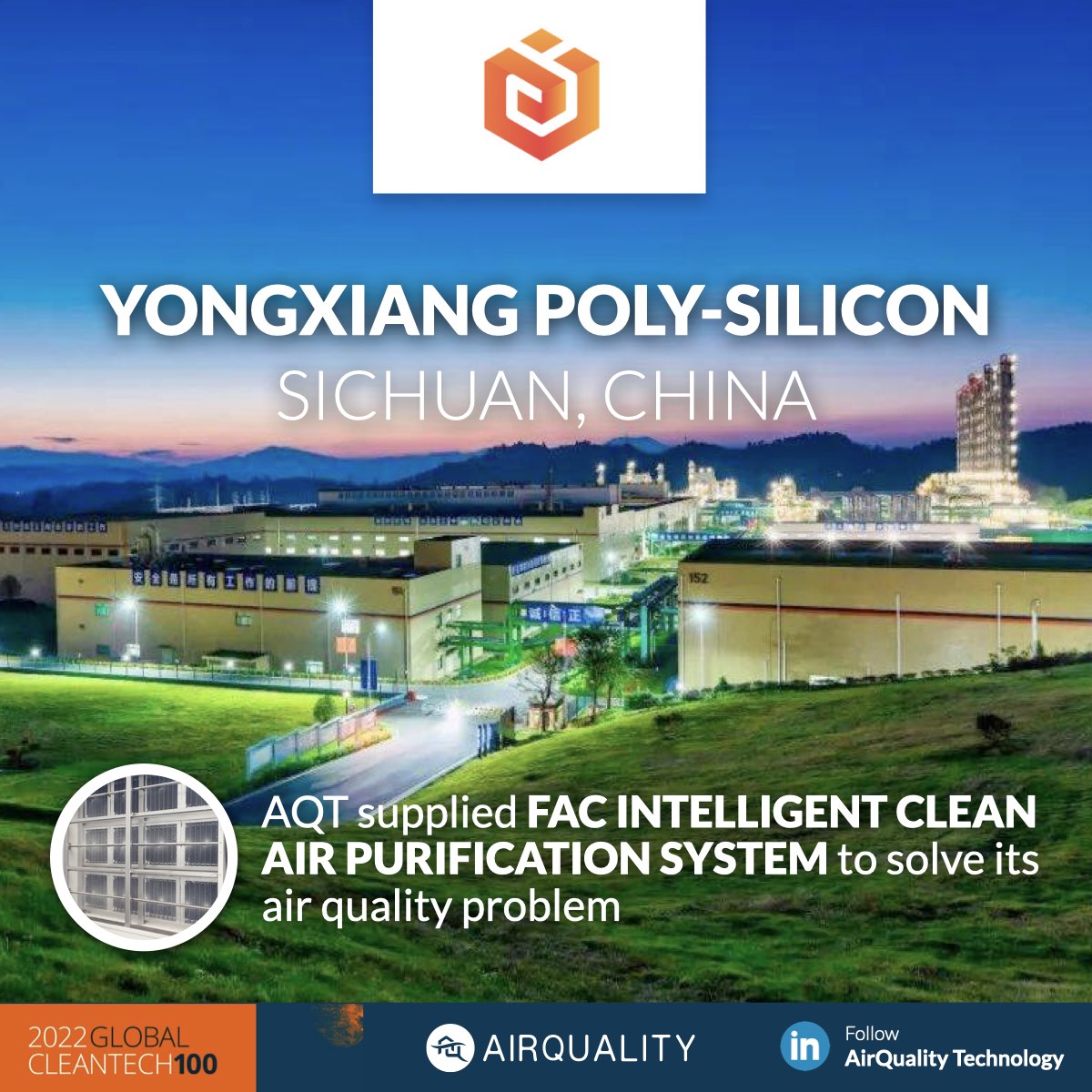

Sichuan Yongxiang polysilicon wafer workshop oil mist purification project

Customer Introduction

Yongxiang New Energy, founded in 2017, is a large-scale private enterprise established by a strong alliance and co-funding between Sichuan Yongxiang Company Limited, a leading world-class silicon material company, and LONGi Green Energy, a leading silicon wafer company, specializing in the research and development of high-purity crystalline silicon technology, production and sales. Thanks to continuous technological innovation, in 2022, Yongxiang's crystalline silicon sales exceeded 260,000 tons, with a global market share of about 28%, the world's first for three consecutive years.

Project Requirements

1.The polysilicon water quenching workshop generates a large amount of silicon

powder and oxides during the production process, and these particulate matters not

only pollute the air in the workshop, but also have a serious impact on the

surrounding environment. The emission of silicon powder and oxides not only poses a

threat to the health of workers, but may also adversely affect the lives of the

surrounding residents.

2.At the same time, the silicon wafer production workshop also generates a large

amount of high-temperature and high-concentration oil mist when working. These oil

mists, if directly discharged into the environment, will cause serious pollution to

water, soil and atmosphere, destroying the ecological balance, and may not pass the

environmental protection acceptance.

Solution

For the large amount of silicon powder and oxides generated in polysilicon water quenching workshop, AQT has selected Smart Clean Air Purifier FAC-A and Smart Cleaner FAC-AW to be applied in air conditioning system, which efficiently filters particles and improves the indoor air quality, and at the same time realizes a fully closed and self-managed air purification system through the intelligent control system. For the oil mist generated in the multi-silicon wafer production workshop, AQT selects: FKE-ACK auto cleaning air cleaner + FUV-K High Efficiency UV Light, which is highly efficient in purifying high-temperature and high-concentration oil mist, and at the same time, the equipment can realize the function of automatic cleaning on a regular basis, which greatly reduces the equipment's post maintenance costs.