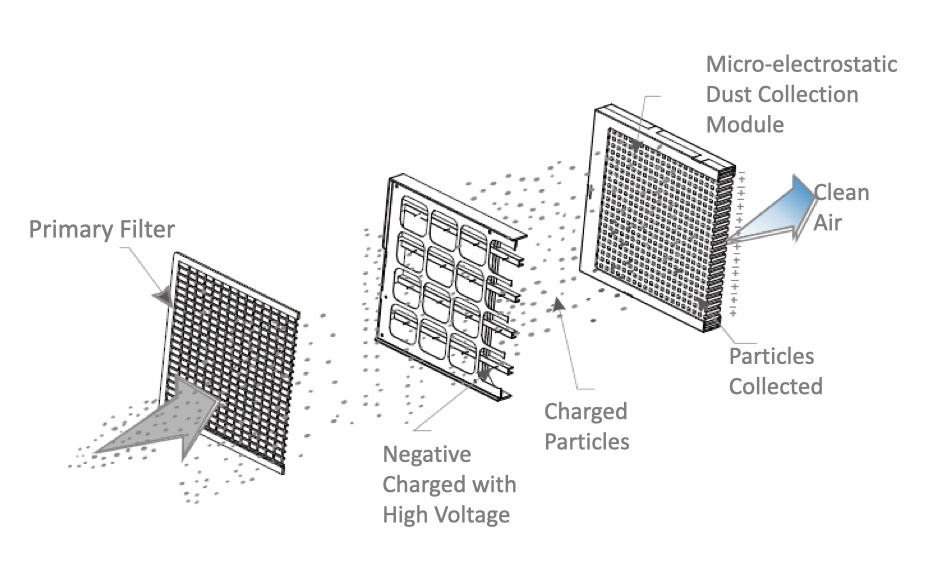

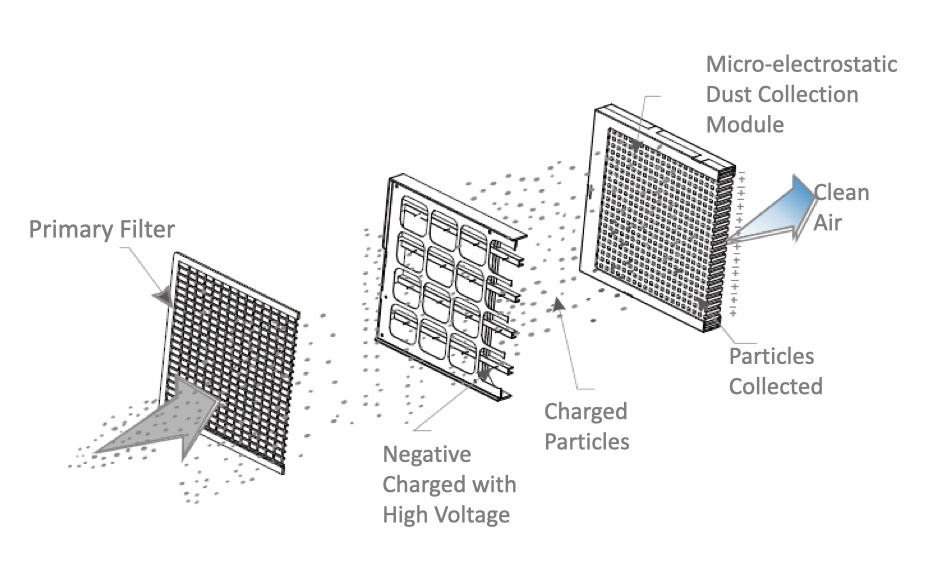

MESP®stands for Micro-electrostatic Precipitation. It is highly efficient at removing airborne particles like PM2.5, fungus, dust, pollen, soot, smoke and powerfully deactivates viruses and bacteria with permanent washable filter. MESP technology is an innovative upgrade from ESP (Electrostatic Precipitator) technology. Compared to ESP, MESP solves the problem of ozone generation, arc and spark.

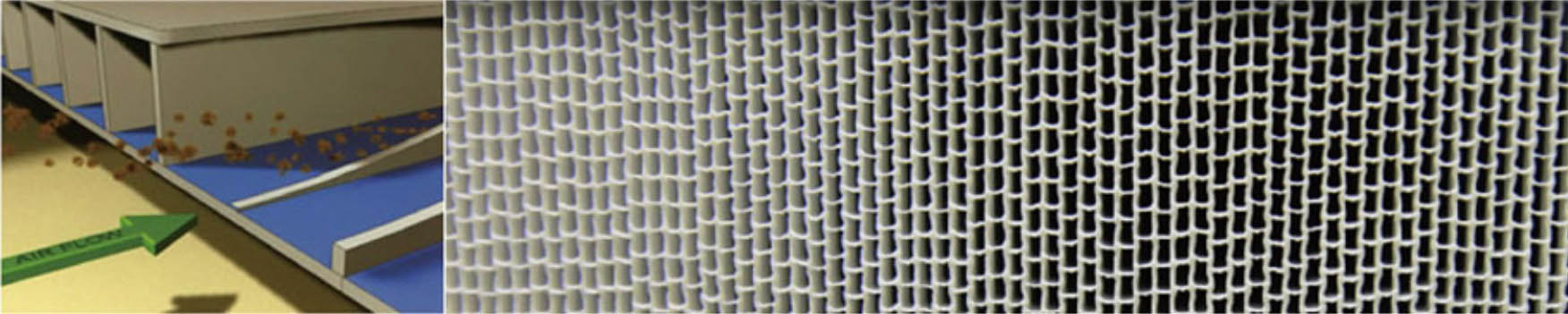

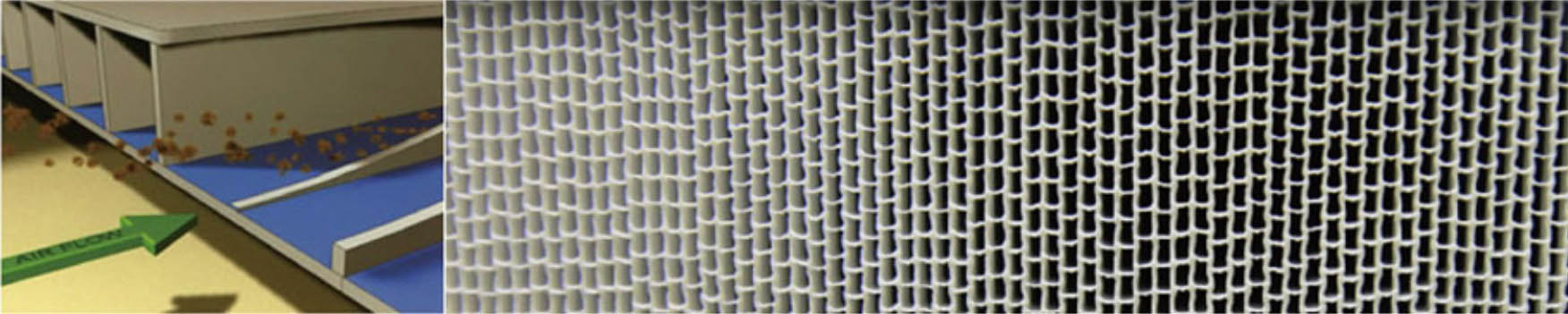

In the MESP system, airborne particles in propelled air flow are electrically charged before passing into honeycomb shaped filter. The filter is formed by layers or rows of tubes which only has 1.8 mm inner spacing and each row contains thin electrode sheets with insulation coating that generate intense electrical fields within the tubes. Charged particles - pollutants, bacteria, germs, viruses - are pulled to the walls of the tubes - and firmly stick.

The polymer tube’s insulation material, prevents current from flowing between electrodes even though with an intense electric field. The unique volt-ampere characteristic curve of MESP technology leads to the result: high voltage and extremely low current without the potential dangers of electrode damage and electric shock, which are traditional ESP product weaknesses.

The unique nano PP-made filter is washable, with a lifespan exceeding 10 years without efficiency loss. The total running cost should be much lower than traditional media filters.

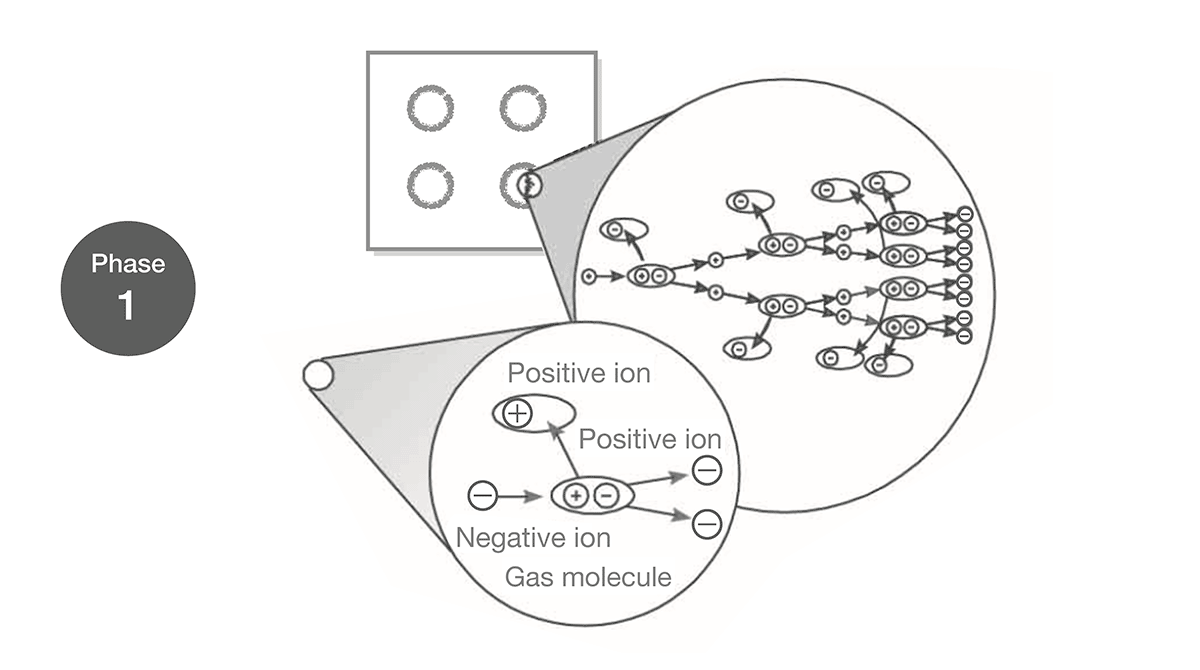

MESP uses a charge grid to generate a corona discharge and release high energy electrons with a voltage of -10.2KV. These electrons form an avalanche effect and generate more and more electrons. Finally they collide with air molecules to produce lots of negative ions.

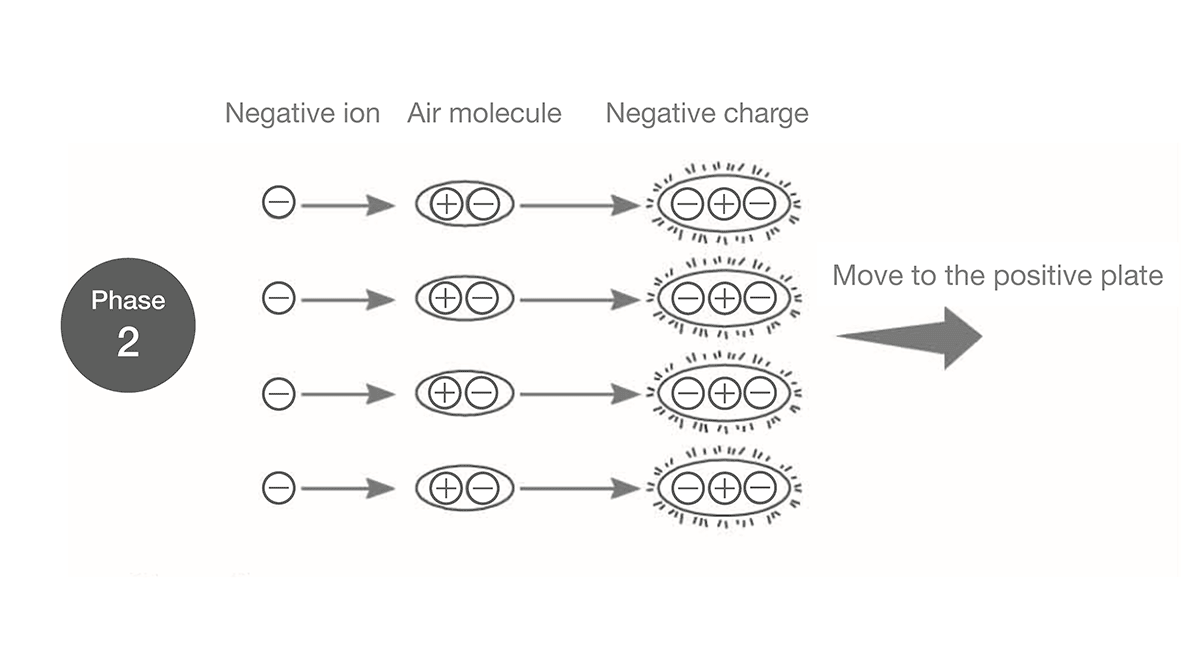

Once away from the corona zone, the negative ions are attracted to the surrounding air, negatively charging the air molecules, which then move towards the MESP positive plate under the action of a strong electric field.

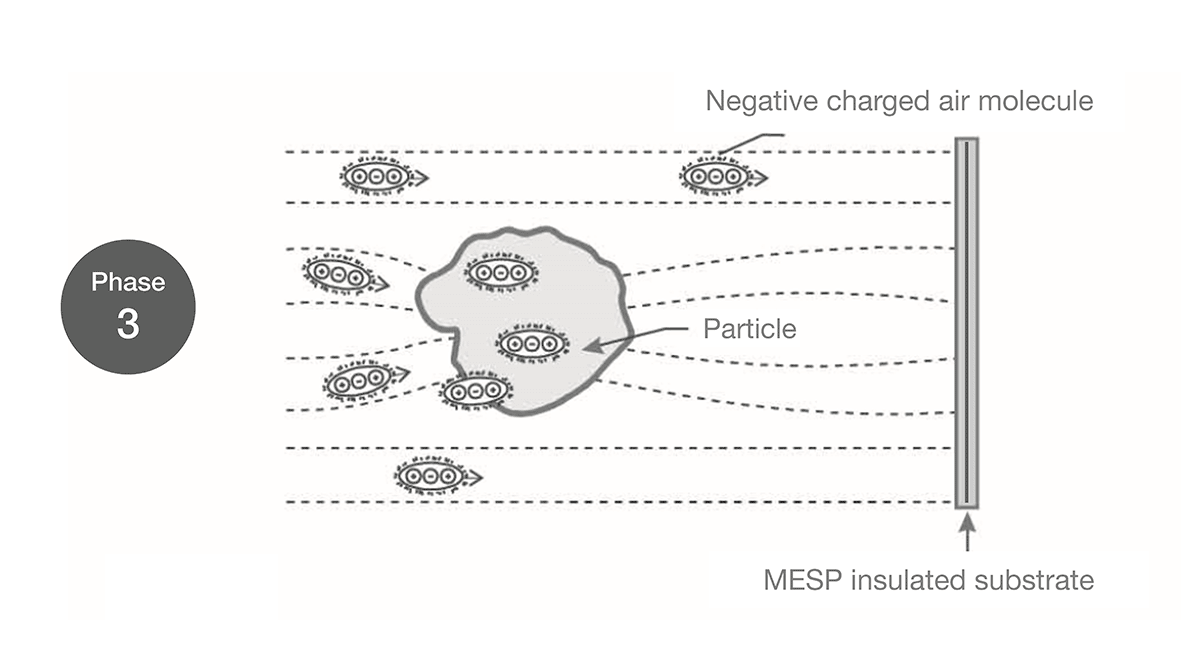

The fine particles will block the negatively charged air molecules from flying and stick them together. The fine particles continue to absorb negatively charged molecules until they are saturated. The fine particles thus carry enough negative charges.

Once the fine particles carry enough negative charges, they move to the positive plate under the action of the dense MESP matrix electric field – and are firmly attracted by it.

Due to the micro-electrostatic filter’s high-voltage electrostatic effect of up to 10,000 volts, the cell wall of bacteria and protein shell of viruses which pass through will be instantly destroyed by strong coulomb force, thereby inactivated, instantly killed.

MESP can high-effiently capture almost all airborne matters even small as 0.01μm in dimension, including biological aerosols with all kinds of viruses and bacteria. In the dust collection module, viruses and bacteria continue to be impacted by high-voltage electric fields, they gradually become carbonized and then inactivated.